Room acoustic treatment plays a crucial role in controlling industrial noise and creating a safe, efficient working environment. Ecotone Systems is a fast-growing and reliable provider of room acoustic treatment solutions for engine test cells, DG rooms, compressor rooms, and other high-noise industrial spaces. Our approach focuses on reducing noise pollution while maintaining smooth airflow and optimal engine performance.

At Ecotone Systems, we design and install acoustic treatments that combine performance with aesthetics. The walls and ceilings are lined with high-quality acoustic materials, including perforated sheets, laminated finishes, and pre-coated clip-in panels that enhance both sound absorption and visual appeal. We also modify standard doors and shutters into robust soundproof doors to ensure complete noise isolation.

Our team ensures that every acoustic installation supports proper air ventilation so engines and machinery do not overheat. This is achieved through advanced ventilation designs, axial flow fans, insulated ducts, acoustic louvers, and splitters that maintain airflow while keeping noise levels under control.

Sound absorption and diffusion are two common challenges in industrial rooms. To address these effectively, Ecotone Systems uses premium-grade rockwool insulation (48/64/96 kg/m³ density) that meets IS 8183 and BS 476 Part II standards. These materials suppress noise reflections, minimize reverberation, and create a controlled acoustic environment suitable for sensitive testing operations.

Without proper acoustic treatment, industrial rooms tend to become excessively noisy, uncomfortable, and unsafe. Our solutions ensure noise reduction at the source, protect workers, and improve the accuracy of engine and equipment testing.

Industrial noise control involves a combination of advanced techniques such as sound enclosures, silencers, acoustic barriers, vibration isolation, and sound-absorbing materials. Ecotone Systems blends these proven methods into a customized solution based on the specific noise source, room size, and operational requirements.

We deliver complete room acoustic treatment systems that include acoustic lining, doors, soundproof windows, and silent ventilation mechanisms. Whether it is a DG room, compressor chamber, or engine test cell, our solutions ensure effective noise reduction with high durability and long-term performance.

Ecotone Systems provides high-performance acoustic solutions built with a strong GI channel grid, tissue fiber laminated rockwool insulation, and perforated GI or aluminum coverings that help achieve excellent noise suppression. Every installation is designed for silent air ventilation, high STC acoustic doors, and clear soundproof viewing windows. The system is fully compatible with DG rooms, compressor rooms, and engine test cells, making it a versatile solution for industrial noise control.

For inquiries, technical support, or detailed project information, reach out to Ecotone Systems. Our team ensures prompt responses and complete guidance for all your acoustic needs.

Have a question or idea? Fill out the form and we’ll get back to you soon!

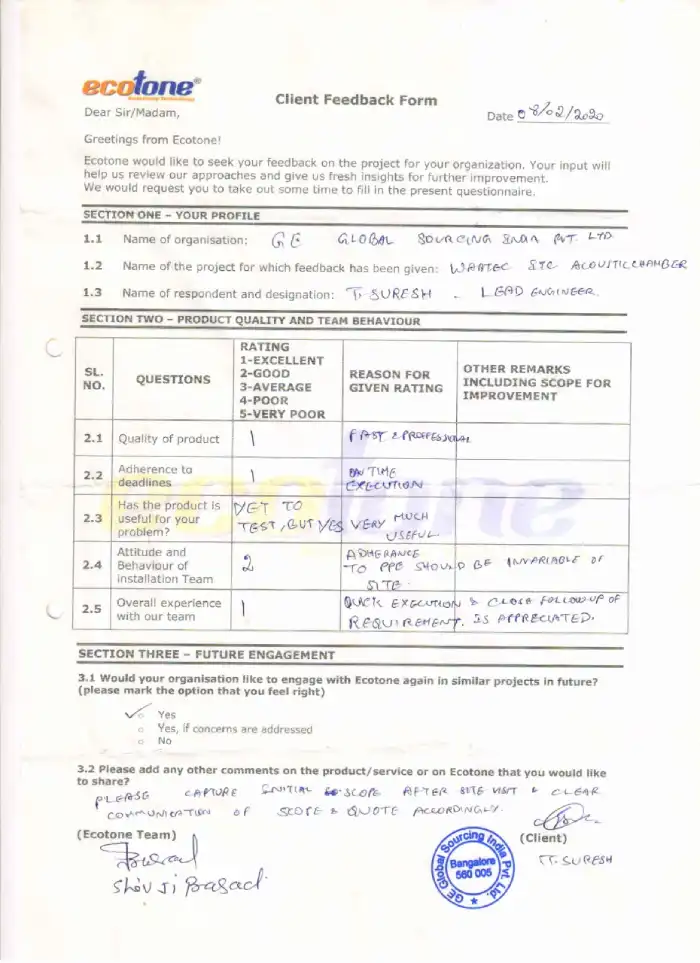

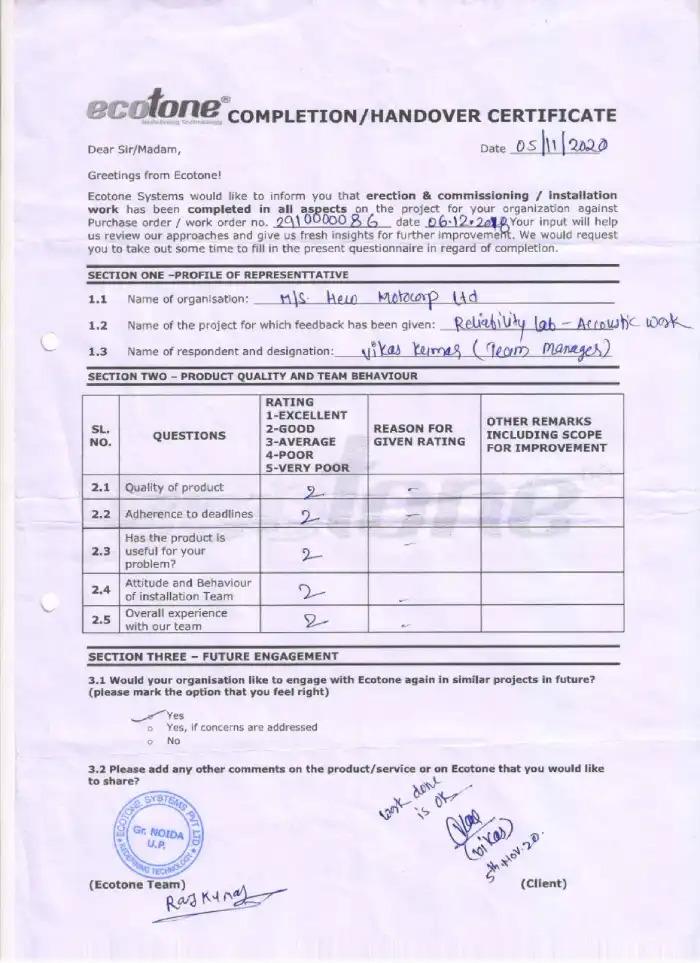

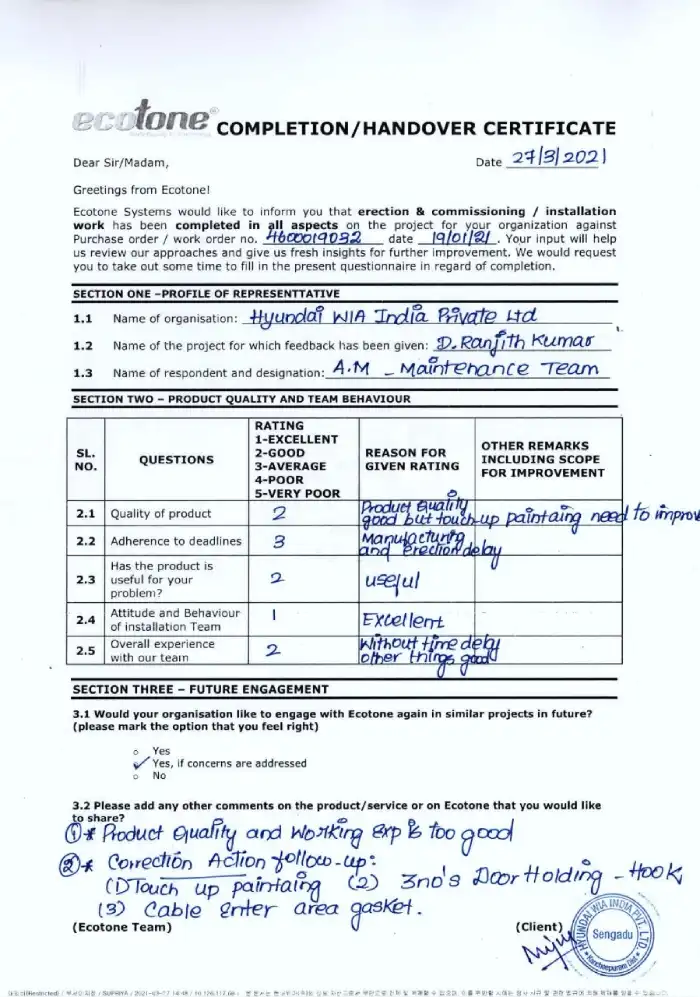

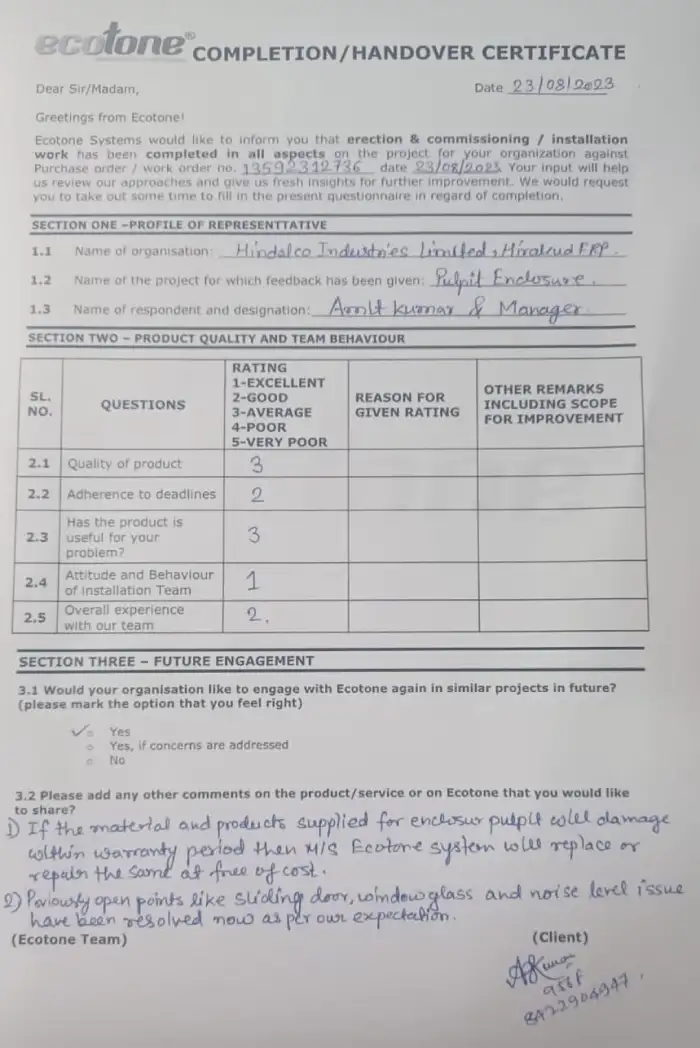

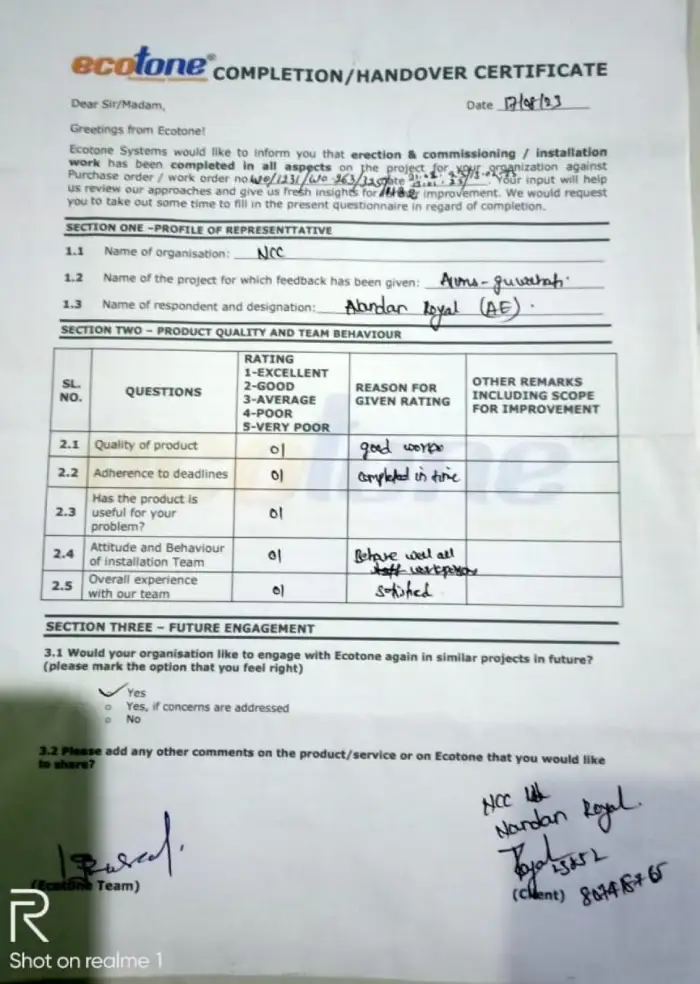

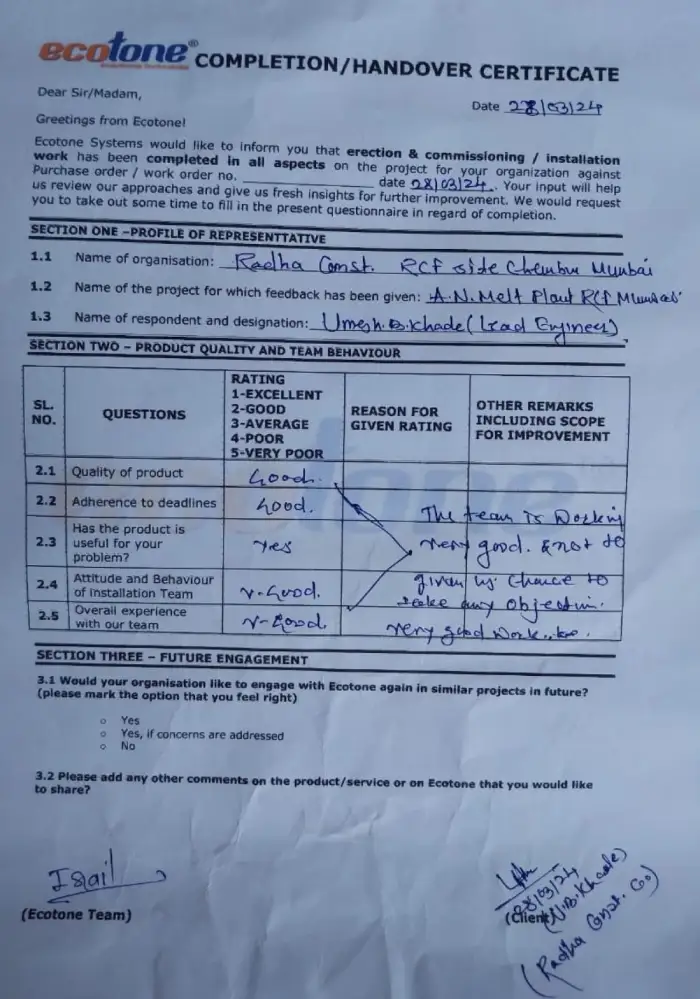

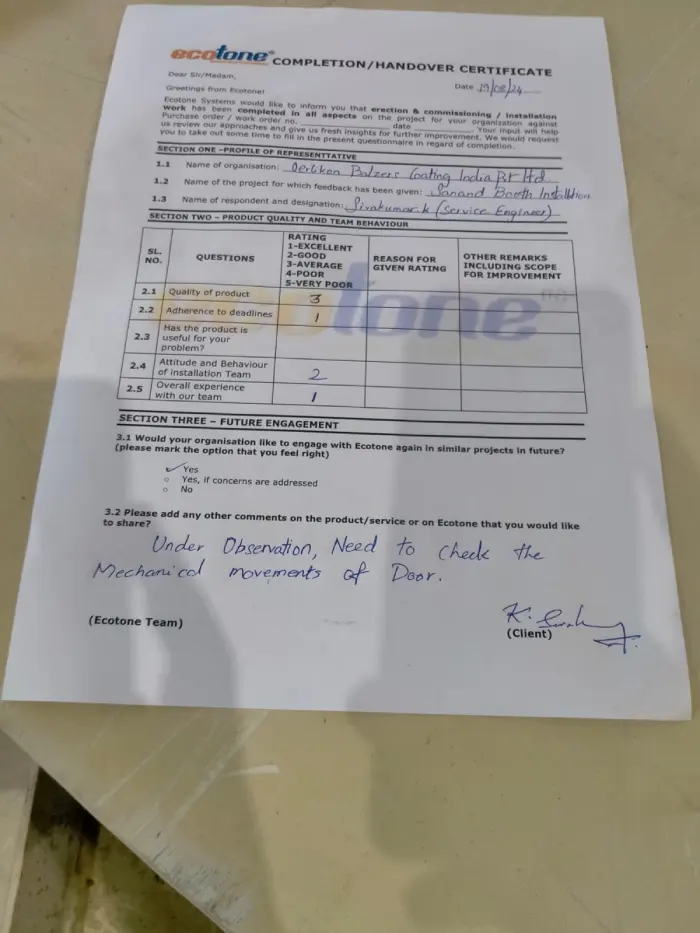

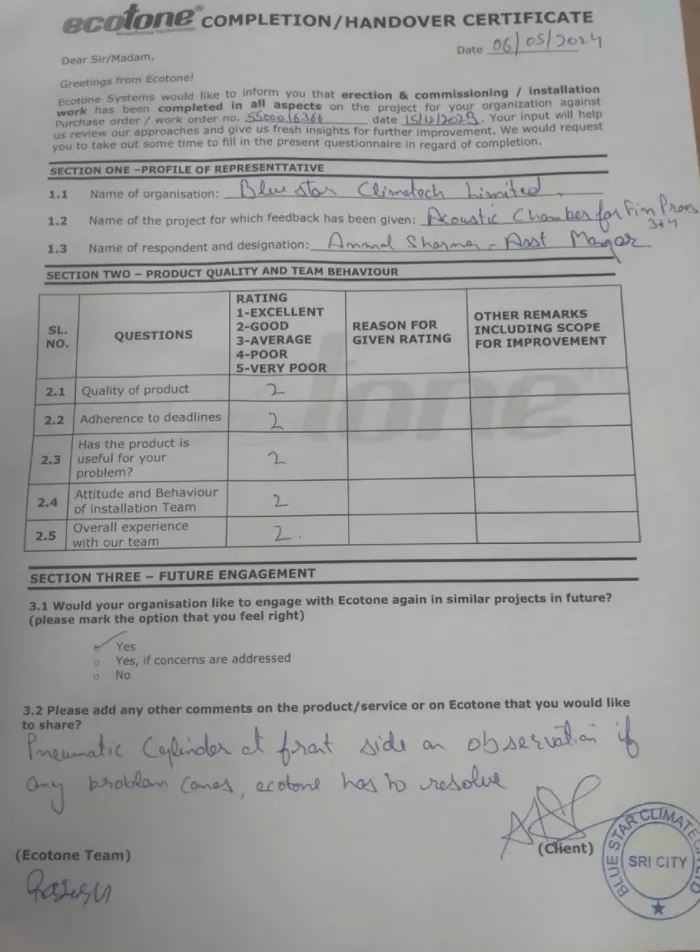

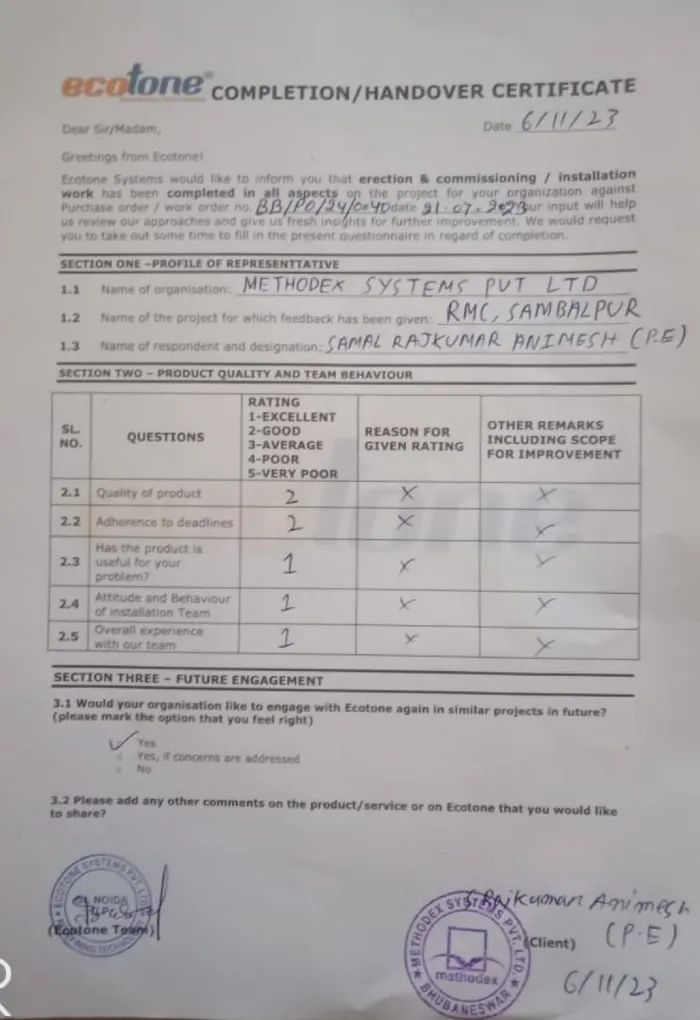

At Ecotone Systems, we value every client relationship. Here’s what our clients have to say about their experience with our acoustic solutions, reflecting our dedication to quality, innovation, and trust

Explore our portfolio of successfully delivered acoustic solutions across diverse industries. Each project reflects our engineering expertise, attention to detail, and commitment to high-performance noise control.