How Full Anechoic Chamber Achieve Complete Sound Absorption

A Full Anechoic Chamber is one of the most advanced acoustic testing environments ever developed. Designed to create near-perfect sound absorption, it provides a space completely free from reflections, echoes, and external noise. Whether used for scientific research, product noise testing, audio engineering, or precision microphone calibration, a Full Anechoic Chamber plays a critical role in achieving accurate acoustic measurements.

In modern acoustics, industries rely heavily on advanced chambers that can simulate an ideal “sound-free” environment. Companies like Ecotone Systems specialize in building high-performance acoustic chambers that help researchers, engineers, and manufacturers understand how sound behaves in controlled settings.

This blog explains in detail how sound absorption works in a Full Anechoic Chamber, how it differs from that in a Semi Anechoic Chamber, and why the design of an Acoustic Anechoic Chamber has become essential for accurate noise measurement. A professional comparison table is also included to improve clarity.

Introduction: Understanding the Role of a Full Anechoic Chamber

A Full Anechoic Chamber is a specialized acoustic space engineered to absorb sound from all directions, floor, walls, and ceiling. The purpose is to eliminate sound reflections so that any emitted noise can be measured exactly as it is, without interference. Unlike a normal room where sound bounces off hard surfaces, a Full Anechoic Chamber mimics the acoustics of an infinite open field.

The demand for these chambers is rising across industries such as aerospace, automotive, electronics, consumer appliances, telecommunication, and audio technology. Engineers use a Full Anechoic Chamber to:

- Study sound pressure levels

- Test product noise emissions

- Perform psychoacoustic evaluations

- Calibrate microphones and sensors

- Measure the directivity of speakers and sound sources

- Research noise control and acoustic material design

While a Semi Anechoic Chamber also eliminates reflections, it includes a solid reflective floor for vehicle or equipment testing. A Full Anechoic Chamber, on the other hand, absorbs sound from every direction, making it the most precise environment available.

As industries increasingly prioritize acoustic quality and noise compliance, the need for reliable Acoustic Anechoic Chamber technology continues to grow.

How Sound Travels and Why It Must Be Controlled

Before understanding how sound absorption works, it’s important to know how sound behaves in a normal environment.

1. Sound Reflection

When sound waves hit a hard surface, they bounce back. This causes:

- Echo

- Reverberation

- Distorted measurements

- Poor speech clarity

- Unpleasant noise buildup

2. Sound Diffusion

Some surfaces scatter sound in different directions, reducing direct reflections but not eliminating them.

3. Sound Absorption

Absorptive materials convert sound energy into heat through internal friction. Standard rooms lack adequate absorption for accurate testing.

A Full Anechoic Chamber is designed to eliminate both reflection and diffusion, creating a pure, reflection-free acoustic field.

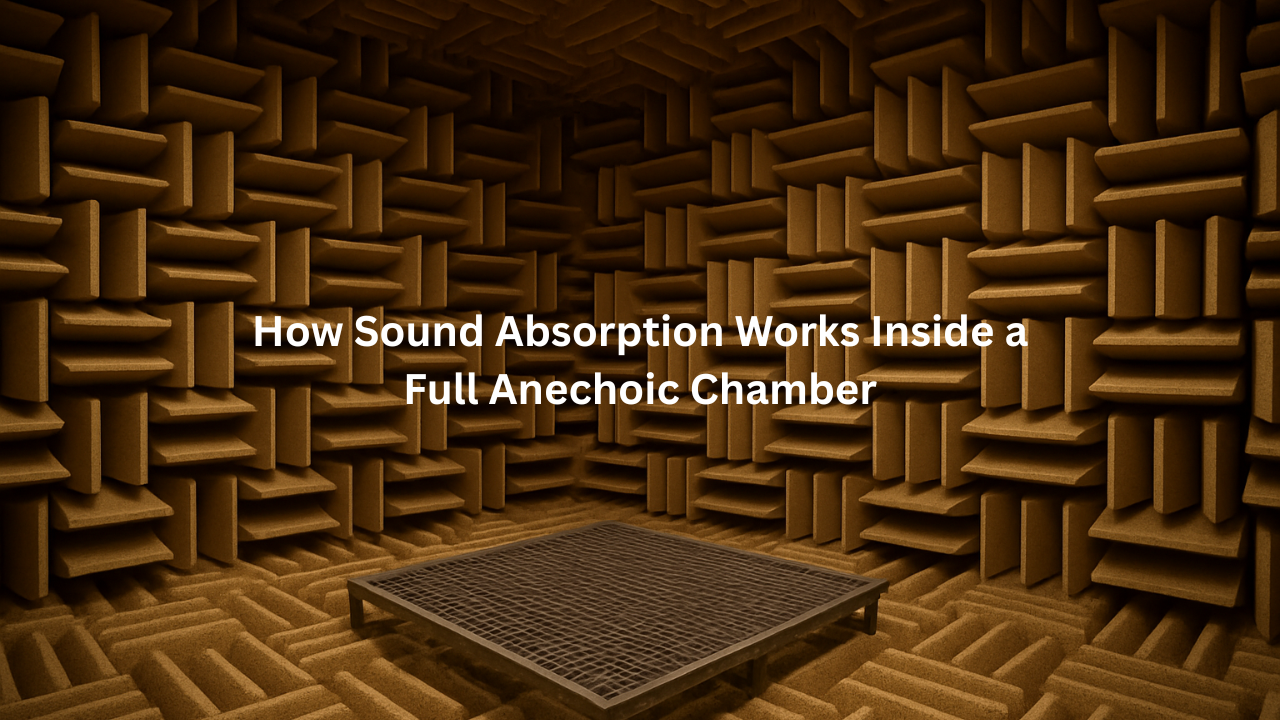

How Sound Absorption Works Inside a Full Anechoic Chamber

The internal structure of a Full Anechoic Chamber is a carefully engineered combination of design principles, geometry, and high-performance materials. Here is how sound absorption works step by step:

1. Wedge or Pyramid-Shaped Absorbers

The most important component of a Full Anechoic Chamber is its acoustic wedge system. These wedges are constructed from:

- Glass wool

- Melamine foam

- Polyurethane foam

- Mineral fiber

- Advanced composite materials

The wedge shape causes multiple internal reflections, gradually absorbing energy until nearly all sound is eliminated.

How They Work

When a sound wave enters a wedge:

- It passes through the tapered end

- Gets trapped deeper inside

- Undergoes multiple reflections

- Loses energy with each bounce

- Converts to heat via friction

- Exits as near-zero sound

A properly engineered wedge system can achieve Noise Reduction Coefficient (NRC) values above 0.99, making the chamber acoustically “dead”.

2. Free-Field Environment Simulation

A Full Anechoic Chamber simulates a free-field environment—meaning sound behaves as if it is outdoors in an infinite open space. This is achieved by:

- Zero reflections

- Uniform sound propagation

- Controlled temperature and humidity

- Low background noise levels

- Absorbers are placed on all surfaces

This environment enables accurate measurement of sound:

- Directivity

- Source strength

- Radiation patterns

- Frequency response

- Harmonics and distortion

3. Floating, Vibration-Isolated Structure

To prevent external vibrations and structure-borne noise, a Full Anechoic Chamber uses:

- Floating floors

- Spring isolation systems

- Air-mount isolators

- Vibration-damping pads

- Double-wall construction

This ensures that tests remain unaffected by:

- Vehicle movement

- Construction activity

- HVAC systems

- Footsteps

- Building vibrations

4. Precision-Engineered Doors and Seals

The door of a Full Anechoic Chamber is one of the most challenging components to design. It must provide:

- High sound insulation

- Zero leakage

- Easy movement

- Magnetic or mechanical sealing

- Flush surface alignment

Even a tiny air gap could compromise the chamber’s acoustic performance.

5. Reverberation Time Control

The goal of a Full Anechoic Chamber is to achieve reverberation time (RT60) close to zero. While it is technically impossible to reach absolute zero, advanced chambers can achieve:

- RT60 below 0.1 seconds

- Background noise levels as low as 10–15 dB(A)

This level of silence allows engineers to detect even the faintest sound emissions.

Professional Comparison Table

Below is a clean, professional comparison between a Full Anechoic Chamber, a Semi Anechoic Chamber, and a general Acoustic Anechoic Chamber.

Table: Comparison of Different Anechoic Chamber Types

| Feature | Full Anechoic Chamber | Semi Anechoic Chamber | Acoustic Anechoic Chamber (General) |

| Sound Absorption | All six surfaces (floor, walls, ceiling) | Absorbs on all surfaces except the reflective floor | Varies based on design |

| Used For | Precision acoustic testing, microphone calibration, research | Vehicle noise test, equipment testing | Mixed acoustic experiments |

| Floor Type | Mesh or suspended floor | Solid reflective floor | Depends on the model |

| Reflection Level | Near-zero reflections | Partial reflections | Moderate to low reflections |

| Testing Accuracy | Very high | High | Medium to high |

| Typical Applications | Audio engineering, psychoacoustics, R&D labs | Automotive, machinery, industrial testing | General acoustics |

| Background Noise | Extremely low | Low | Varies |

| Cost | Highest | Moderate | Depends on configuration |

Why a Full Anechoic Chamber Delivers the Highest Accuracy

Because a Full Anechoic Chamber absorbs sound from every direction, it provides the most reliable data for:

- Speaker and headphone testing

- Fan and motor noise analysis

- Industrial noise diagnostics

- Product comparison and certification

- Audio device calibration

- Research-grade experimentation

Unlike a Semi Anechoic Chamber, which allows floor reflections, a Full Anechoic Chamber eliminates reflective interference entirely.

Inside the Internal Design Structure

Creating an ideal Full Anechoic Chamber requires a combination of scientific and architectural elements:

1. Acoustic Wedges

Length, density, spacing, and material type determine the absorption efficiency.

2. Metal or Concrete Shell

Prevents external noise infiltration.

3. Vibration Isolation Floor

Floating floors ensure that external disturbances do not affect the readings.

4. Non-Reflective Test Flooring

Wire mesh, tensioned net, or perforated steel walkways.

5. Acoustic Door with Multi-Layer Seals

Prevents leakage of even high-frequency noise.

6. HVAC Noise Control

Duct silencers and isolated airflow systems maintain airflow without compromising silence.

Applications Where Full Anechoic Chambers Are Essential

A Full Anechoic Chamber is widely used in:

1. Automotive Testing

To analyze engine noise, electric vehicle components, and interior acoustics.

2. Electronics & Consumer Appliances

Noise testing of fans, compressors, speakers, and sensors.

3. Aerospace Industry

Testing aircraft sensors, actuators, and communication devices.

4. Microphone and Sensor Calibration

Ensuring product precision through reflection-free measurement.

5. Research and Development

Universities and laboratories use chambers for advanced acoustic experiments.

6. Audio Transducer Development

For designing high-fidelity speakers, headphones, and studio monitors.

Differences Between Full Anechoic and Semi Anechoic Chambers

While both are types of Acoustic Anechoic Chambers, they differ in:

Full Anechoic Chamber

- Complete absorption

- Suspended floor

- Maximum accuracy

- Used for high-precision testing

Semi Anechoic Chamber

- Reflective floor for vehicle or heavy equipment

- Absorbs only on the sides and the ceiling

- Suitable for machinery and automotive applications

A Full Anechoic Chamber is ideal when absolute silence and precise measurements are required.

Why Industries Choose Professional Anechoic Chambers

Choosing a high-quality chamber is essential to obtain reliable acoustic test results.

A leading provider like Ecotone Systems supplies engineered solutions that meet demanding international standards and high-precision requirements.

A poorly designed chamber can lead to:

- Incorrect acoustic readings

- Faulty product certification

- Design flaws in audio components

- Regulatory compliance challenges

This is why industries invest in advanced Full Anechoic Chambers built with precision, durability, and accurate absorption performance.

Conclusion

A Full Anechoic Chamber is an engineering marvel that creates a space almost entirely free from sound reflections and external noise. Through carefully designed wedge absorbers, vibration isolation, and precision construction, it provides the most accurate environment for acoustic testing.

Understanding how sound absorption works inside a Full Anechoic Chamber helps engineers, researchers, and manufacturers appreciate its scientific importance. Whether comparing it with a Semi Anechoic Chamber or a general Acoustic Anechoic Chamber, the Full version remains unmatched for accuracy, stability, and acoustic purity.

As industries continue advancing toward quieter, more efficient, and technically superior products, the role of professionally designed anechoic chambers will only become more critical.

FAQs

1. What is a Full Anechoic Chamber?

A Full Anechoic Chamber is a room designed to absorb sound from all directions, eliminating reflections and external noise for precision acoustic testing.

2. How does it differ from a Semi Anechoic Chamber?

A Semi Anechoic Chamber has a solid reflective floor, while a Full Anechoic Chamber absorbs sound on all surfaces, including the floor.

3. What materials are used for sound absorption?

Acoustic wedges made from melamine foam, mineral wool, polyurethane foam, or composite materials absorb sound energy efficiently.

4. What industries use these chambers?

Automotive, aerospace, consumer electronics, research labs, audio engineering, and manufacturing industries rely on Full Anechoic Chambers.

5. Can a Full Anechoic Chamber achieve absolute silence?

Absolute silence is impossible, but advanced chambers can reduce noise to extremely low levels, often below 15 dB(A).