Introduction

Ecotone Systems is proud to announce the successful completion of an advanced Acoustic Enclosure for a 1010 kVA Diesel Generator (DG) set for Birlanu Limited (formerly HIL Limited) at their Balasore, Odisha facility. This project was undertaken with a strong focus on industrial noise control, environmental compliance, and long-term operational reliability.

Industrial diesel generators of high capacity are essential for uninterrupted power supply, yet they generate substantial noise during operation. Managing this noise effectively is critical to ensure worker comfort, regulatory compliance, and minimal impact on surrounding areas. Understanding these requirements, Ecotone Systems delivered a customized and performance-driven acoustic solution tailored specifically to the client’s operational environment.

Project Scope and Engineering Approach

The project involved detailed acoustic analysis, customized design development, precision manufacturing, and on-site installation of the enclosure system. Our engineering team began by evaluating the generator specifications, site layout, ambient noise conditions, and the required sound attenuation levels.

Based on this assessment, a specially engineered acoustic enclosure was designed to significantly reduce noise emissions while ensuring efficient airflow for generator cooling. Ventilation systems were carefully integrated to maintain optimal operating temperatures without compromising acoustic performance. Structural strength and durability were key considerations, ensuring that the enclosure can withstand demanding industrial conditions and varying weather environments.

Throughout the manufacturing process, strict quality control measures were implemented to ensure high acoustic insulation performance, structural stability, and long service life. The final installation was executed with precision to guarantee seamless integration with the DG set and easy accessibility for routine maintenance and servicing.

Performance and Compliance

The installed acoustic enclosure effectively controls operational noise and supports compliance with applicable environmental and industrial standards. The solution not only enhances workplace safety and comfort but also contributes to improved community relations by minimizing sound impact beyond the facility premises.

By combining acoustic expertise with practical engineering design, Ecotone Systems delivered a reliable, durable, and high-performance solution that aligns with the client’s operational objectives.

Client and Location

Client: Birlanu Limited (formerly HIL Limited)

Location: Balasore, Odisha

Project Type: Acoustic Enclosure for 1010 kVA DG Set

Additional Services by Ecotone Systems

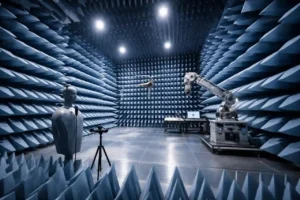

In addition to acoustic enclosures for diesel generators, Ecotone Systems offers a comprehensive range of industrial noise control and acoustic solutions. Our expertise includes the design and development of Anechoic Chambers for precision acoustic testing and research applications. We also manufacture high-performance Acoustic Doors engineered for superior sound insulation in industrial and commercial environments. For outdoor and perimeter noise control requirements, we provide durable and efficient Noise Barrier systems designed to reduce sound transmission and environmental impact.

Our solutions are fully customized to meet specific project requirements, ensuring optimal performance, regulatory compliance, and long-term reliability.

Contact Us

If you are planning a new industrial project or seeking effective noise control solutions for existing facilities, Ecotone Systems is ready to support you with technically sound and performance-driven systems.

Get in touch with our team to discuss your project requirements, request technical consultation, or receive a customized proposal. We are committed to delivering engineered acoustic solutions that ensure performance, compliance, and lasting value.