Acoustic Ceiling Baffles for Effective Industrial Noise Control

Acoustic Ceiling Baffles play a crucial role in controlling noise inside large industrial facilities where high ceilings and hard surfaces create excessive echo and reverberation. In manufacturing plants, warehouses, and production units, uncontrolled sound can impact worker safety, communication, and overall productivity. By installing Ceiling Baffles, industries can significantly reduce reflected noise, improve speech clarity, and create a more balanced acoustic environment without disrupting daily ongoing operations.

Introduction to Industrial Noise Challenges

Industrial environments are typically large open spaces with minimal soft surfaces. When machines operate continuously, sound waves bounce repeatedly between floors, ceilings, and walls. This leads to prolonged reverberation time, making the environment louder than the actual machine output.

High noise levels can reduce worker concentration, slow down communication, and increase stress levels. In some cases, it can even lead to long-term hearing concerns. Addressing these challenges requires strategic sound control solutions that are effective yet adaptable to complex layouts.

Why Industrial Facilities Need Noise Control

Noise control in industrial settings is not only about comfort but also about efficiency and safety. When employees struggle to communicate clearly, workflow disruptions occur. Miscommunication in production areas can lead to operational errors and safety risks.

Installing Acoustic Ceiling Baffles helps manage sound at the source of reflection, especially in facilities with high ceilings and limited wall space. These vertically suspended panels absorb sound waves from both sides, improving overall acoustic balance across the workspace. In large manufacturing plants or warehouses, they perform significantly better than many traditional sound treatments because they interact directly with airborne sound.

Key Benefits of Acoustic Ceiling Baffles

One of the primary advantages of Acoustic Ceiling Baffles is their ability to reduce reverberation time in large open industrial halls. By absorbing sound energy before it continues to reflect across hard surfaces, they create a more controlled and balanced acoustic environment.

Improved sound absorption leads to clearer communication between workers. In production zones where instructions must be delivered quickly and accurately, reduced echo enhances speech intelligibility. This supports smoother coordination and reduces the likelihood of misunderstandings.

Another important benefit is improved workplace safety. When background noise levels are lowered, employees can better hear alarms, warning signals, and equipment alerts. This contributes to a safer and more responsive work environment.

From a design perspective, Hanging Baffles provide flexibility. They can be customized in size, spacing, thickness, and material to suit the specific acoustic needs of a facility. Whether used in assembly plants or power generation units, Industrial Acoustic Baffles adapt easily to various structural conditions.

Additionally, Acoustic Baffles can be installed without major structural modifications. Since they are suspended from ceilings, they do not interfere with machinery placement or wall-mounted equipment. This makes them suitable for both retrofit projects and new industrial constructions.

Types of Acoustic Baffles Used in Industries

There are several variations of Acoustic Baffles designed for industrial use. Fabric-wrapped mineral fiber options are commonly used where sound absorption performance is the primary concern. Metal perforated variants with acoustic infill are preferred in environments that require durability and protection against impact.

Polyester-based Hanging Baffles are lightweight and resistant to moisture, making them suitable for facilities with humidity variations. Custom-engineered Industrial Acoustic Baffles can also be designed for high-temperature zones or dust-heavy environments.

The selection depends on environmental conditions, fire safety requirements, and the level of noise control needed. Proper acoustic assessment ensures the right combination of material and configuration for optimal results.

Ceiling Baffles vs Wall Panels

In industrial settings, wall space is often occupied by machinery, storage racks, electrical panels, and operational equipment. This limits the effectiveness of wall-mounted acoustic solutions.

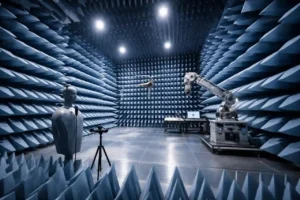

Acoustic Ceiling Baffles offer a clear advantage because they utilize unused overhead space. Their vertical orientation increases surface exposure to sound waves, improving absorption efficiency. Unlike flat panels installed directly on ceilings, Sound Baffles suspended vertically interact with sound from multiple directions, making them particularly effective in large halls.

For facilities with open layouts and high ceilings, ceiling-mounted solutions typically provide better overall acoustic performance compared to wall treatments alone.

Industries That Benefit the Most

Manufacturing plants, automotive workshops, textile factories, power plants, warehouses, and food processing facilities all experience high noise levels due to equipment operation. In such environments, Industrial Acoustic Baffles significantly enhance sound management.

Warehouses with metal roofing and concrete flooring often experience strong echo issues. Installing Acoustic Ceiling Baffles reduces this reflection and creates a more controlled workspace. Similarly, in production units where multiple machines operate simultaneously, Sound Baffles help balance ambient noise levels.

Installation Considerations

Successful installation begins with understanding the facility’s acoustic profile. Ceiling height, machinery placement, and dominant noise frequencies all influence design decisions. Proper spacing of Hanging Baffles ensures uniform sound absorption across the area.

It is also important to consider airflow, lighting fixtures, and fire safety systems during installation. Professional acoustic planning ensures that the placement of Acoustic Baffles complements other building systems without obstructing operations.

Maintenance and Durability

Modern Industrial Acoustic Baffles are engineered for long-term durability. Many options are resistant to dust accumulation and moisture exposure. Regular inspection and basic cleaning are typically sufficient to maintain performance.

In environments with heavy industrial activity, selecting robust materials ensures that Acoustic Ceiling Baffles remain effective over time. Proper installation further enhances their lifespan and reliability.

Cost-Effectiveness Over Time

Although the initial investment may vary depending on project scale, Acoustic Ceiling Baffles provide long-term value. Improved communication reduces operational errors. Enhanced safety lowers accident-related risks. A comfortable acoustic environment can also improve employee morale and productivity.

When viewed as a long-term infrastructure improvement, Acoustic Baffles deliver measurable returns by enhancing overall facility performance.

Environmental and Compliance Benefits

Noise control plays a significant role in meeting occupational health guidelines. By reducing excessive reverberation and controlling background noise, Industrial Acoustic Baffles help facilities align with safety standards.

Many acoustic materials are also manufactured using sustainable processes, contributing to environmentally responsible construction practices. Selecting high-quality Sound Baffles supports both compliance and sustainability goals.

Additional Services of Ecotone Systems

In addition to Acoustic Ceiling Baffles, Ecotone Systems provides comprehensive industrial noise control solutions tailored to diverse operational environments.

Soundproof Curtains are flexible and adaptable noise barriers designed to minimize sound transmission between specific sections of a facility. They are particularly useful in areas where temporary or movable partitions are required. These systems provide targeted sound control without permanent structural changes.

A Soundproof Door is another essential component in industrial acoustic planning. Designed to prevent airborne noise leakage, it is commonly installed in generator rooms, compressor enclosures, testing chambers, and control rooms. Combining Soundproof Door solutions with Hanging Baffles ensures a complete approach to noise management.

By integrating Acoustic Ceiling Baffles with complementary products such as Soundproof Curtains and specialized door systems, industrial facilities can achieve comprehensive and reliable sound control.

Conclusion

Excessive noise in industrial facilities can affect productivity, safety, and communication. Implementing Acoustic Ceiling Baffles provides an effective method for reducing reverberation and improving overall acoustic performance in large open spaces.

From enhanced worker comfort to long-term operational benefits, the advantages are substantial. When combined with Industrial Acoustic Baffles and other sound management solutions, facilities can create a balanced and compliant working environment without disrupting daily operations.

Investing in properly designed Acoustic Baffles is a strategic decision that supports both performance and workplace well-being in modern industrial settings.