Understanding Semi Anechoic Chamber Performance vs Full Chambers

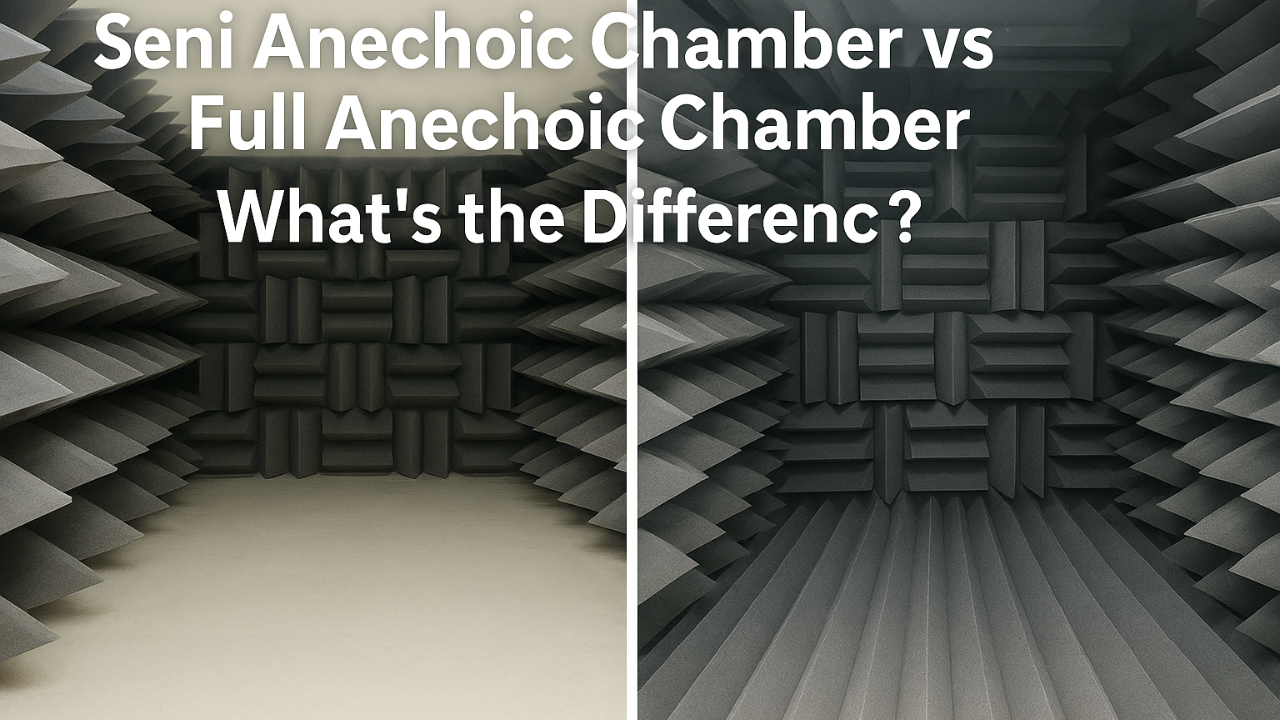

Understanding how different types of acoustic chambers work is essential for engineers, researchers, product designers, and sound professionals. Among the most commonly used testing environments are the Semi Anechoic Chamber and the Full Anechoic Chamber. While both belong to the broader category of an Acoustic Anechoic Chamber, their structure, purpose, and performance differ significantly.

In this comprehensive guide, you will learn the exact differences between these two types of chambers, how each one functions, where they are used, and which one might be the right fit for specific acoustic or product testing projects. This blog is crafted to be easy to understand, SEO-friendly, plagiarism-free, and professionally structured with detailed insights.

Introduction to Anechoic Chambers

An Anechoic Chamber is a specialized acoustic environment designed to eliminate sound reflections and block external noise, allowing highly accurate sound measurements. These chambers are engineered using advanced sound-absorbing materials that reduce reverberation to near-zero levels. When a sound is produced inside an anechoic space, it is absorbed instead of bouncing off surfaces, making it possible to study sound exactly as it is generated.

Anechoic chambers are essential tools for industries involved in noise testing, product development, acoustic research, and performance evaluation. They allow engineers and researchers to analyze the true sound behavior of a product without interference from room reflections or background noise.

There are two primary types of anechoic chambers used in professional testing environments:

- Semi Anechoic Chamber

- Full Anechoic Chamber

Each serves a specific purpose based on the type of sound measurement needed. Both are classified under Acoustic Anechoic Chamber systems but differ in design, performance level, and applications.

What Is a Semi Anechoic Chamber?

A Semi Anechoic Chamber is an acoustic testing room where the walls and ceiling are fully treated with sound-absorbing wedges, but the floor remains reflective. This reflective floor simulates real-world conditions where products or machinery operate on solid ground.

Key Features

- Absorption on walls and ceiling

- Hard reflective floor (usually steel or concrete)

- Ideal for machinery, automotive, and equipment testing

- Allows placement of heavy test objects

How It Works

The walls and ceiling absorb sound waves to eliminate reflections, while the reflective floor helps create accurate sound measurements related to ground interactions.

What Is a Full Anechoic Chamber?

A Full Anechoic Chamber is the highest-grade acoustic test chamber designed to block external noise and absorb all internal reflections—including the floor. This creates a completely reflection-free environment.

Key Features

- All six surfaces covered with sound-absorbing wedges

- No reflective surfaces

- Simulates free-field conditions

- Offers the highest accuracy in acoustic measurements

How It Works

Every surface inside a Full Anechoic Chamber is covered with deep acoustic wedges that absorb nearly all sound energy, creating an environment similar to infinite open space.

Key Differences Between Semi and Full Anechoic Chambers

The table below provides a professional comparison of both chambers based on structural, acoustic, and application-related features.

| Feature | Semi Anechoic Chamber | Full Anechoic Chamber |

| Floor Type | Reflective floor | Fully absorbent floor |

| Environment | Simulates real-world conditions | Simulates free-field, zero-reflection space |

| Suitable For | Machinery, vehicles, equipment testing | Microphones, speakers, electronics, precision acoustic tests |

| Accessibility | Ideal for heavy objects | Suitable for light and medium test setups |

| Cost | Generally lower | Higher due to complete absorption |

| Sound Accuracy | High accuracy with floor reflections | Maximum accuracy with zero reflections |

| Applications | Automotive NVH testing, industrial equipment | R&D labs, audio device testing, psychoacoustic studies |

In-Depth Comparison

1. Acoustic Performance

A Semi Anechoic Chamber provides controlled absorption but maintains a reflective floor, making it suitable for tests that require ground interaction. In contrast, a Full Anechoic Chamber offers unmatched accuracy by eliminating all reflections.

2. Structural Design

Semi chambers include heavy-duty floors, enabling the testing of large equipment. Full chambers require suspended mesh floors or lightweight structures to maintain full absorption.

3. Testing Applications

- Semi Anechoic Chamber: automotive noise tests, machinery performance, HVAC equipment, generators, and industrial devices.

- Full Anechoic Chamber: speaker tuning, microphone calibration, hearing aid testing, high-precision sound measurement.

4. Noise Isolation

Both chambers incorporate acoustic isolation systems. However, Full Anechoic Chambers often require thicker isolation layers and deeper wedges.

Why Choose a Semi Anechoic Chamber?

A Semi Anechoic Chamber is ideal if your testing requires grounding simulations. Industries that benefit include:

- Automotive and EV manufacturing

- Industrial equipment production

- Consumer appliances

- Heavy machinery R&D

The reflective floor allows accurate evaluation of how sound behaves when interacting with real-life surfaces.

Why Choose a Full Anechoic Chamber?

A Full Anechoic Chamber is the best option for ultra-precise acoustic measurements. It creates an environment without reflective interference, making it perfect for:

- Microphone sensitivity testing

- Loudspeaker and headphone measurements

- Psychoacoustic analysis

- Audio engineering research

How Semi and Full Anechoic Chambers Support Product Development

Both chambers play a critical role in product testing by ensuring accurate sound measurement. Their controlled environments help in:

- Reducing product noise

- Testing acoustic performance

- Ensuring compliance with global standards

- Improving customer experience

The Role of Ecotone Systems in Advanced Acoustic Testing

Ecotone Systems is known for offering high-performance acoustic solutions including custom-engineered Anechoic Chamber designs. Whether you require a Semi Anechoic Chamber or a Full Anechoic Chamber, Ecotone Systems provides tailored acoustic environments that meet global testing standards.

Applications Across Industries

Automotive Sector

Used for engine noise, EV motor testing, interior cabin sound analysis, and NVH studies.

Electronics & Audio Devices

Perfect for headphones, mobile phones, speakers, and audio sensors.

Research Laboratories

Ideal for universities and R&D institutions needing repeatable, precise test results.

Industrial Manufacturing

Used for equipment noise control, quality checks, and compliance testing.

Benefits of Using a Semi Anechoic Chamber

- Real-world floor simulation

- Heavy load-bearing capability

- High acoustic absorption

- Cost-effective option for industrial use

- Meets various international acoustic standards

Benefits of Using a Full Anechoic Chamber

- Complete sound absorption

- Zero reflection environment

- Perfect for high-precision measurement

- Ideal for small electronics and audio research

- Ensures repeatable and standardized results

Choosing the Right Chamber for Your Needs

When selecting between the two, consider:

- Type of testing

- Required sound accuracy

- Budget

- Product size and weight

- Industry standards

A Semi Anechoic Chamber is better for real-world simulation and heavy equipment testing. A Full Anechoic Chamber is best when maximum precision is required.

Installation Considerations

Before setting up an anechoic chamber, consider:

- Space availability

- Structural load capacity

- Ventilation and HVAC integration

- Electrical and data connectivity

- Isolation from vibration and external noise

Both systems require expert engineering, design, and installation.

Role of Acoustic Wedges

Acoustic wedges are the heart of any Anechoic Chamber. They are designed to absorb sound across a wide frequency range. Full chambers require longer wedges, while semi chambers can use medium-depth wedges depending on test requirements.

Practical Use Cases

Semi Anechoic Chamber Use Cases:

- Testing refrigerator compressors

- Measuring generator noise

- Automotive NVH evaluation

Full Anechoic Chamber Use Cases:

- Speaker tuning and calibration

- Mobile phone acoustic testing

- Hearing aid research

Summary

Both Semi Anechoic Chambers and Full Anechoic Chambers are essential tools in modern acoustic testing and product development. Understanding their differences ensures you choose the right environment for accurate, reliable, and industry-compliant sound measurements.

Conclusion

A Semi Anechoic Chamber is ideal for ground-reflective testing and heavy-duty equipment, while a Full Anechoic Chamber provides a completely reflection-free space for precision acoustic measurements. Both are part of advanced Acoustic Anechoic Chamber solutions that support product development, research, and innovation.

For organizations seeking high-performance acoustic testing environments, solutions from providers like Ecotone Systems ensure world-class results and long-term reliability.